4 20Ma Current Sensor

4 20Ma Current Sensor - Web the 4 ma to 20 ma current loop is a common method of transmitting sensor information in many industrial process monitoring applications—typically in systems monitoring pressure, temperature, ph, flow, or other physical factors. 4 to 20 ma current loop overview. Web only one current level can be present at any time. However, voltage drops and the number Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! Web the device is a split core current sensor with a 24mm opening.

Follow this simple guide and we will show you a few tips to make it fast and easy. 4ma represents 0% input level. Web only one current level can be present at any time. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals!

Current loops are ideal for data transmission because of their inherent insensitivity to electrical noise. 0 to 100% 4 to 20ma signal. If the measured value rises above or falls below the configured thresholds, an alert is sent over the wireless network. 4ma represents 0% input level. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is.

The 4 to 20 ma current loop is a very robust sensor signaling standard. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is. Follow this simple guide and we will show you a few tips to make it fast and easy. However, voltage drops and the number It is also much.

It is also much simpler and cost effective. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! It is also much simpler and cost effective. It is an ideal method of transferring process information because current does not change as it travels from.

It is good to know the basics when troubleshooting or when choosing the best output signal for your application. It is also much simpler and cost effective. It is also much simpler and cost effective. This loop can be used for power measuring or monitoring purposes. 4 to 20 ma current loop overview.

It is good to know the basics when troubleshooting or when choosing the best output signal for your application. This loop can be used for power measuring or monitoring purposes. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is. Web the wireless sensors designed and manufactured by radio bridge provide full.

Web the device is a split core current sensor with a 24mm opening. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver..

It is also much simpler and cost effective. Follow this simple guide and we will show you a few tips to make it fast and easy. The 4 to 20 ma current loop is a very robust sensor signaling standard. Allows up to 4ma to power external input circuitry. Sensors or transducers are usually designed to measure a range of.

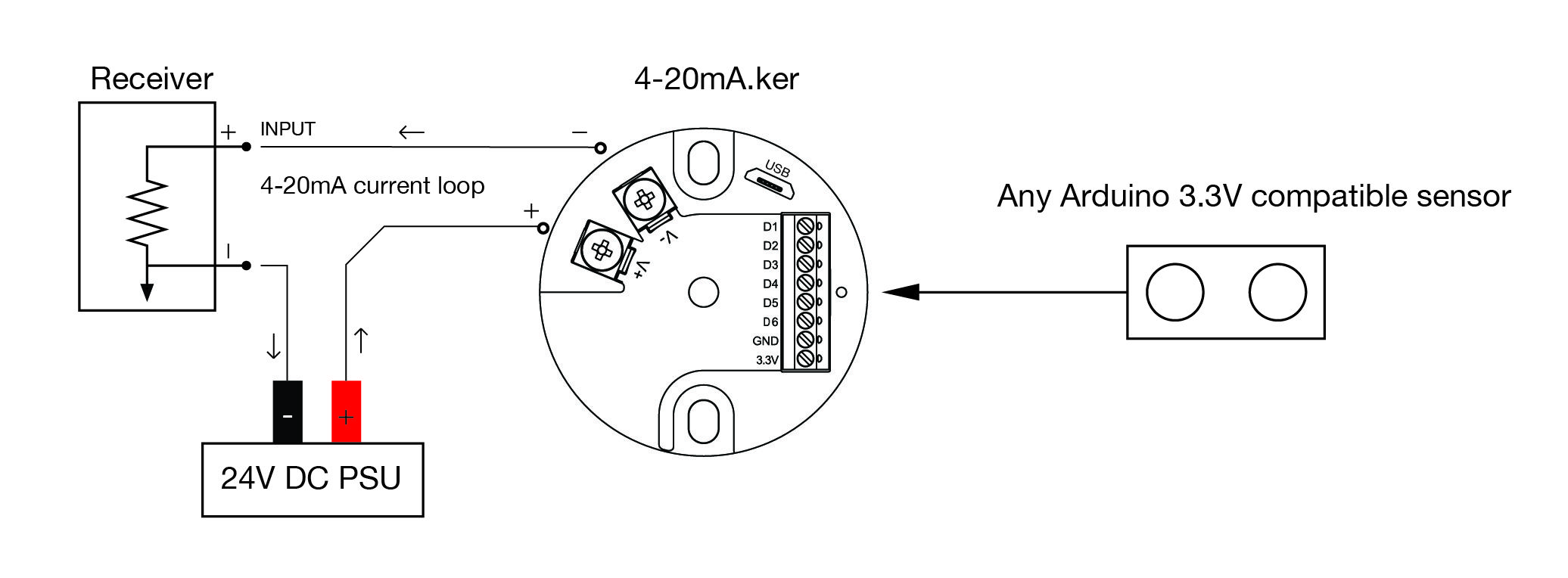

In a current loop, the current signal is drawn from a dc power supply, flows through the transmitter, into the controller and then back to the power supply in a series circuit. It is also much simpler and cost effective. Allows up to 4ma to power external input circuitry. Follow this simple guide and we will show you a few.

The 4 to 20 ma current loop is a very robust sensor signaling standard. Web the wireless sensors designed and manufactured by radio bridge provide full sensor to cloud solutions for internet of things (iot) applications. It is also much simpler and cost effective. If the measured value rises above or falls below the configured thresholds, an alert is sent.

This loop can be used for power measuring or monitoring purposes. It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver. Web this document describes how to manage the voltage drops in a 4 to 20 ma current loop, and how to determine the proper power supply voltage for.

The 4 to 20 ma current loop is a very robust sensor signaling standard. 20ma represents 100% input level. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! Current loops are ideal for data transmission because of their inherent insensitivity to electrical noise..

4 20Ma Current Sensor - 0 to 100% 4 to 20ma signal. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! Error analysis and overtemperature characterization data as well as hardware design and software are provided. Current loops are ideal for data transmission because of their inherent insensitivity to electrical noise. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is known as the measurand. It is good to know the basics when troubleshooting or when choosing the best output signal for your application. It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver. The 4 to 20 ma current loop is a very robust sensor signaling standard. Follow this simple guide and we will show you a few tips to make it fast and easy. It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver.

Follow this simple guide and we will show you a few tips to make it fast and easy. 4 to 20 ma current loop overview. Allows up to 4ma to power external input circuitry. Web the 4 ma to 20 ma current loop is a common method of transmitting sensor information in many industrial process monitoring applications—typically in systems monitoring pressure, temperature, ph, flow, or other physical factors. Web only one current level can be present at any time.

Web only one current level can be present at any time. 4 to 20 ma current loop overview. If the measured value rises above or falls below the configured thresholds, an alert is sent over the wireless network. Follow this simple guide and we will show you a few tips to make it fast and easy.

Web the 4 ma to 20 ma current loop is a common method of transmitting sensor information in many industrial process monitoring applications—typically in systems monitoring pressure, temperature, ph, flow, or other physical factors. 0 to 100% 4 to 20ma signal. The 4 to 20 ma current loop is a very robust sensor signaling standard.

Web the device is a split core current sensor with a 24mm opening. 0 to 100% 4 to 20ma signal. 4 to 20 ma current loop overview.

Web Only One Current Level Can Be Present At Any Time.

It is also much simpler and cost effective. The 4 to 20 ma current loop is a very robust sensor signaling standard. Web the device is a split core current sensor with a 24mm opening. 4ma represents 0% input level.

0 To 100% 4 To 20Ma Signal.

4 to 20 ma current loop overview. Web the wireless sensors designed and manufactured by radio bridge provide full sensor to cloud solutions for internet of things (iot) applications. In a current loop, the current signal is drawn from a dc power supply, flows through the transmitter, into the controller and then back to the power supply in a series circuit. It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver.

If The Measured Value Rises Above Or Falls Below The Configured Thresholds, An Alert Is Sent Over The Wireless Network.

20ma represents 100% input level. Sensors or transducers are usually designed to measure a range of values of the measured parameter, which is. Web this single guide makes you a master of the measurement of 4 to 20 ma, which is widely used as sensor outputs and control signals! Web the 4 ma to 20 ma current loop is a common method of transmitting sensor information in many industrial process monitoring applications—typically in systems monitoring pressure, temperature, ph, flow, or other physical factors.

Error Analysis And Overtemperature Characterization Data As Well As Hardware Design And Software Are Provided.

However, voltage drops and the number Web this document describes how to manage the voltage drops in a 4 to 20 ma current loop, and how to determine the proper power supply voltage for the loop. It is an ideal method of transferring process information because current does not change as it travels from transmitter to receiver. Follow this simple guide and we will show you a few tips to make it fast and easy.