Metric Bolt Specification Chart

Metric Bolt Specification Chart - Download and print metric coarce threads clearance and tap drill chart. Web the following table chart defines standard metric external thread size m1.6 to m18 per. These thread sizes and classes represent bolts and screws, as well, as other standard external threads. After printing, measure the ruler in the margin to ensure correct scale. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch: Web a metric iso screw thread is designated by the letter m followed by the value of the nominal diameter d (the maximum thread diameter) and the pitch p, both expressed in millimetres and separated by a dash or sometimes the multiplication sign, × (e.g.

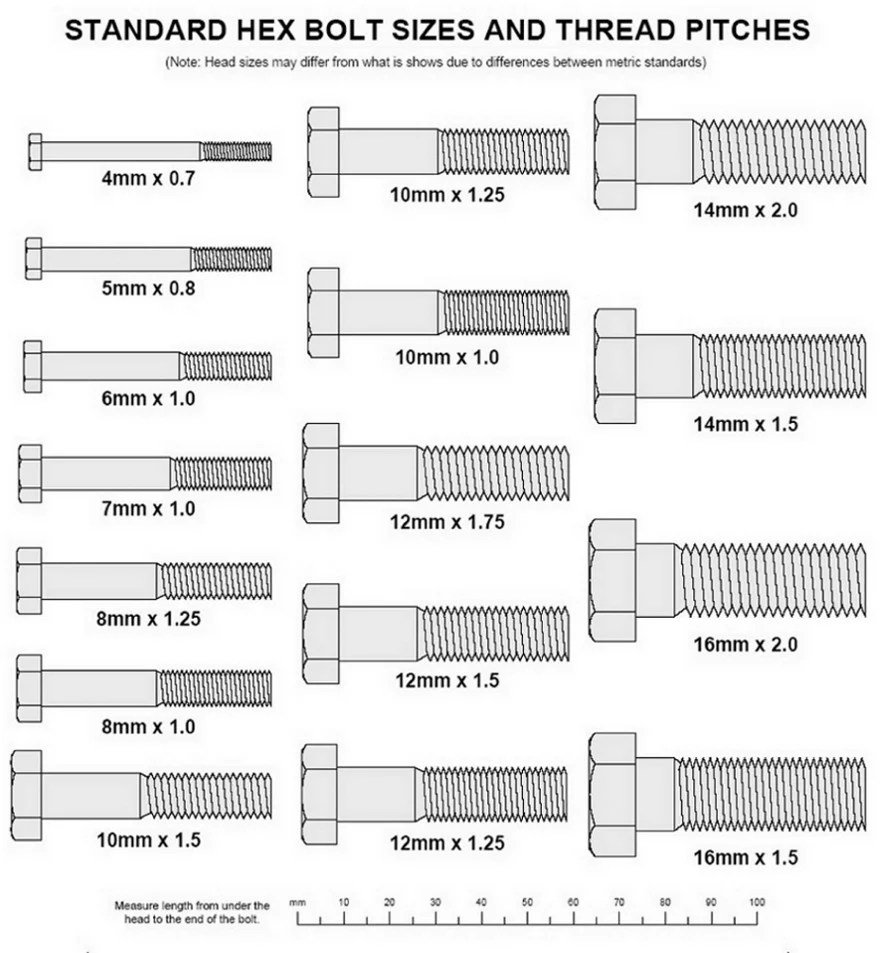

Multiply decimal by 25.4 millimeter to decimal: Download and print metric coarce threads clearance and tap drill chart. See boltdepot.com/tools for more details. Head to the end of the bolt. Wrench sizes m10, m12, m14 and m22 are different.

After printing, measure ruler above to ensure correct scale. Wrench sizes m10, m12, m14 and m22 are different. Thread pitch = the distance between threads. Web the ulitmate metric screw thread resource: These thread sizes and classes represent bolts and screws, as well, as other standard external threads.

Asme b5.1m table of dimensions and tolerances, inch and (metric) mm units. Higher strength nuts or nuts of equal strength may be a suitable substitute provided bolt standard allows. Multiply decimal by 25.4 millimeter to decimal: See boltdepot.com/tools for more details. Imperial and metric measurements included.

Web standard metric hex bolt sizes and thread pitches scale check: For metric bolts strength is according iso 898 mechanical properties of fasteners made of carbon steel and alloy steel described by property classes with designations 4.6, 4.8, 5.8, 8.8, 9.8, 10.9 and 12.9. Web compatible denotes commercially available nut having suitable mechanical properties and dimensional configuration or style which.

Head to the end of the bolt. The clearance drill sizes listed are the most commonly used sizes. For metric bolts strength is according iso 898 mechanical properties of fasteners made of carbon steel and alloy steel described by property classes with designations 4.6, 4.8, 5.8, 8.8, 9.8, 10.9 and 12.9. Make sure to print this chart to actual size.

Divide top # by bottom # decimal to millimeter: Pitch diameter of threads calculator and formula. Head sizes may differ from what is shows due to differences between metric standards). Higher strength nuts or nuts of equal strength may be a suitable substitute provided bolt standard allows. Web each metric standard is product specific.

Web metric screw thread chart. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch: After printing, measure ruler above to ensure correct scale. Web metric thread size explained. Multiply decimal by 25.4 millimeter to decimal:

Web below is a table common fastener sizes and lengths and their us (inch) decimal and closest fraction equivalent. Web this british standard gives the general dimensions and tolerances of black hexagon bolts, screws and nuts with iso metric threads, in diameters from 5 mm to 68 mm inclusive. Web a metric iso screw thread is designated by the letter.

Pitch diameter of threads calculator and formula. Web the following table chart defines standard metric external thread size m1.6 to m18 per. Guide to design criteria for bolted and riveted joints. Wrench sizes m10, m12, m14 and m22 are different. Web size chart with hex bolts din 931 and iso 4014.

Our thread size chart covers m1.6 up to m68. Web standard metric hex bolt sizes and thread pitches scale check: Web size chart with hex bolts din 931 and iso 4014. Web each metric standard is product specific. Guide to design criteria for bolted and riveted joints.

Web a metric iso screw thread is designated by the letter m followed by the value of the nominal diameter d (the maximum thread diameter) and the pitch p, both expressed in millimetres and separated by a dash or sometimes the multiplication sign, × (e.g. Web below is a table common fastener sizes and lengths and their us (inch) decimal.

The maximum load at which a material exhibits a specific permanent deformation. For example din 931 is for partially threaded coarse thread metric hex cap screws. Asme b5.1m table of dimensions and tolerances, inch and (metric) mm units. Thread pitch = the distance between threads. Web in this article, we’ll go through a complete guide of bolts, which involves bolts.

Metric Bolt Specification Chart - The clearance drill sizes listed are the most commonly used sizes. Web a metric iso screw thread is designated by the letter m followed by the value of the nominal diameter d (the maximum thread diameter) and the pitch p, both expressed in millimetres and separated by a dash or sometimes the multiplication sign, × (e.g. Thread pitch = the distance between threads. Imperial and metric measurements included. Web the following table chart defines standard metric external thread size m1.6 to m18 per. After printing, measure the ruler in the margin to ensure correct scale. Wrench sizes m10, m12, m14 and m22 are different. The specification used to produce the corresponding inch series fastener is ansi b 18.2.1. Higher strength nuts or nuts of equal strength may be a suitable substitute provided bolt standard allows. Din 960 is the specification for partially threaded fine thread metric hex cap screws.

Web each metric standard is product specific. Thread pitch = the distance between threads. After printing, measure the ruler in the margin to ensure correct scale. After printing, measure the ruler in the margin to ensure correct scale. The maximum load in tension (pulling apart) which a material can withstand before breaking or fracturing.

Web metric screw thread chart. Web the following table chart defines standard metric external thread size m1.6 to m18 per. Pitch diameter of threads calculator and formula. Web this british standard gives the general dimensions and tolerances of black hexagon bolts, screws and nuts with iso metric threads, in diameters from 5 mm to 68 mm inclusive.

Head sizes may differ from what is shows due to differences between metric standards). Thread pitch = the distance between threads. Web size chart with hex bolts din 931 and iso 4014.

Imperial and metric measurements included. Asme b5.1m table of dimensions and tolerances, inch and (metric) mm units. For metric bolts strength is according iso 898 mechanical properties of fasteners made of carbon steel and alloy steel described by property classes with designations 4.6, 4.8, 5.8, 8.8, 9.8, 10.9 and 12.9.

After Printing, Measure Ruler Above To Ensure Correct Scale.

Imperial and metric measurements included. Wrench sizes m10, m12, m14 and m22 are different. The specification used to produce the corresponding inch series fastener is ansi b 18.2.1. It is common to designate metric fine threads with the capital m plus an indication to their nominal outer diameter and their pitch:

Asme B5.1M Table Of Dimensions And Tolerances, Inch And (Metric) Mm Units.

Web the following table chart defines standard metric external thread size m1.6 to m18 per. The maximum load at which a material exhibits a specific permanent deformation. Guide to design criteria for bolted and riveted joints. Web compatible denotes commercially available nut having suitable mechanical properties and dimensional configuration or style which will make it possible to obtain the desired bolt load.

For Example Din 931 Is For Partially Threaded Coarse Thread Metric Hex Cap Screws.

Web in this article, we’ll go through a complete guide of bolts, which involves bolts definition, types & uses, dimensions explain, and the standard bolt sizes chart in metric and imperial. Web standard metric hex bolt sizes and thread pitches scale check: Web a metric iso screw thread is designated by the letter m followed by the value of the nominal diameter d (the maximum thread diameter) and the pitch p, both expressed in millimetres and separated by a dash or sometimes the multiplication sign, × (e.g. Head to the end of the bolt.

Web The Ulitmate Metric Screw Thread Resource:

In our metric screw size chart above, metric thread size is denoted by a series of numbers and letters that encapsulate various dimensions including the major diameter, thread pitch, and thread type. The maximum load in tension (pulling apart) which a material can withstand before breaking or fracturing. After printing, measure the ruler in the margin to ensure correct scale. Multiply decimal by 25.4 millimeter to decimal: