Sensor To Detect Vibration

Sensor To Detect Vibration - Texas instrument’s sensortag is a great product that showcases ti’s bluetooth low energy system as well as 10 different sensors. Web a vibration sensor is a device that measures the vibration characteristics in a machine, system, or piece of equipment. Shock sensors and knock sensors can be used to detect closing doors, excessive vibration in machinery, or collisions in remote controlled vehicles. Ifm vibration monitoring systems help you avoid unplanned downtime in the middle of production by providing vibration data to assess and evaluate the condition of your machine in real time. When a machine’s vibration measurements change, though, it can be an indication of. Serving around the globebased in houston, txaward winning technology

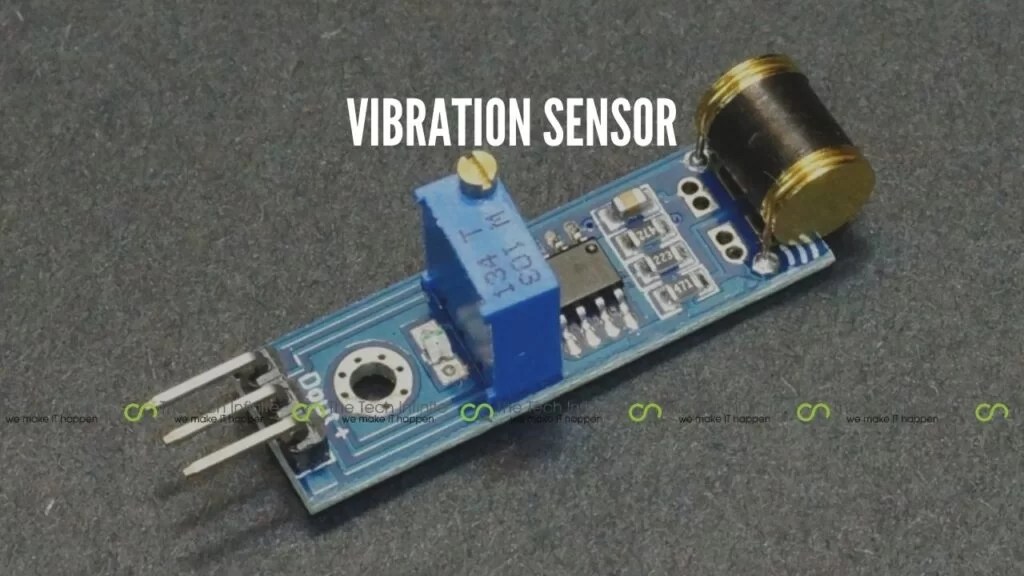

Top brandsbuy it now availablehuge selectiondaily deals Now that we know what vibration is, let’s look at the different types of sensors to monitor vibration. Web the primary sensors used in this process include accelerometers, velocity sensors, and displacement sensors. Web vibration is most commonly measured using a ceramic piezoelectric sensor or accelerometer. Web types of vibration sensor.

Top brandsbuy it now availablehuge selectiondaily deals Most accelerometers rely on the use of the piezoelectric effect, which occurs when a voltage is generated across certain types of crystals as they are stressed. Web the primary sensors used in this process include accelerometers, velocity sensors, and displacement sensors. Web similar to how there are sensors that will detect light or emit light on the same principle, there are piezoelectric sensors: Web a vibration sensor is a device that measures the amount and frequency of vibration in a given system, machine, or piece of equipment.

Web choosing the right vibration sensor is paramount to ensuring accurate data collection and effective maintenance strategies. When a machine’s vibration measurements change, though, it can be an indication of. Therefore, this paper attempts to use vibration sensors to detect the vibration signals emitted during the welding process, together with the current signals and molten pool images to achieve the.

Shock sensors and knock sensors can be used to detect closing doors, excessive vibration in machinery, or collisions in remote controlled vehicles. Web choosing the right vibration sensor is paramount to ensuring accurate data collection and effective maintenance strategies. Vibration sensors can be used to give maintenance teams insight into conditions within key assets that might lead to equipment failure,.

Web vibration monitoring is the process of using sensors to detect the abnormal motion of a machine. Having access to this data allows the user to predict an oncoming fail of such machinery and. Most accelerometers rely on the use of the piezoelectric effect, which occurs when a voltage is generated across certain types of crystals as they are stressed..

Web using an iot vibration sensor allows the user or analyst to test if the vibration levels are too great from shafts or bearings in poor health. It comes in at the incredibly low price of less than $30 (you wonder if ti loses money on these?!). Web types of vibration sensor. Therefore, this paper attempts to use vibration sensors.

Web vibration monitoring is the process of using sensors to detect the abnormal motion of a machine. Web a vibration sensor is a device that measures the amount and frequency of vibration in a given system, machine, or piece of equipment. Top brandsbuy it now availablehuge selectiondaily deals Shock sensors and knock sensors can be used to detect closing doors,.

Web a vibration sensor is a device that measures the vibration characteristics in a machine, system, or piece of equipment. Web accelerometers are the most accurate way to detect vibration, and we’ll learn about them in another article. Web choosing the right vibration sensor is paramount to ensuring accurate data collection and effective maintenance strategies. Web using an iot vibration.

Web a vibration sensor is a device that measures the amount and frequency of vibration in a given system, machine, or piece of equipment. Vibration sensors can be used to give maintenance teams insight into conditions within key assets that might lead to equipment failure, allowing them to predict the m. These sensors are strategically attached to different machinery parts,.

In this blog post, we will provide a comprehensive guide on how to choose the best vibration sensor for your specific needs. Ifm vibration monitoring systems help you avoid unplanned downtime in the middle of production by providing vibration data to assess and evaluate the condition of your machine in real time. Web choosing the right vibration sensor is paramount.

Vibration is not inherently bad — every rotating machine has a unique vibration signature. Web a vibration sensor is a device that measures the vibration characteristics in a machine, system, or piece of equipment. First, we will talk about an accelerometer. Accelerometers are devices that measure the vibration, or acceleration of motion of a structure. This system will use a.

Vibration sensors can be used to give maintenance teams insight into conditions within key assets that might lead to equipment failure, allowing them to predict the m. Web the primary sensors used in this process include accelerometers, velocity sensors, and displacement sensors. Web choosing the right vibration sensor is paramount to ensuring accurate data collection and effective maintenance strategies. Serving.

Sensor To Detect Vibration - Top brandsbuy it now availablehuge selectiondaily deals These sensors are strategically attached to different machinery parts, and their readings are interpreted through vibration analyzers or. Accelerometers are devices that measure the vibration, or acceleration of motion of a structure. But for some projects, you don’t need such high accuracy. Having access to this data allows the user to predict an oncoming fail of such machinery and. Vibration is not inherently bad — every rotating machine has a unique vibration signature. The data gathered from the sensor is the vibration frequency, amplitude, phase angle and the form of the vibration. First, we will talk about an accelerometer. Now that we know what vibration is, let’s look at the different types of sensors to monitor vibration. Ifm vibration monitoring systems help you avoid unplanned downtime in the middle of production by providing vibration data to assess and evaluate the condition of your machine in real time.

But for some projects, you don’t need such high accuracy. Web vibration is most commonly measured using a ceramic piezoelectric sensor or accelerometer. Most accelerometers rely on the use of the piezoelectric effect, which occurs when a voltage is generated across certain types of crystals as they are stressed. Texas instrument’s sensortag is a great product that showcases ti’s bluetooth low energy system as well as 10 different sensors. Serving around the globebased in houston, txaward winning technology

This system will use a light (led) and a sound (buzzer) to let people or other systems nearby know when it senses any unusual movement. Web similar to how there are sensors that will detect light or emit light on the same principle, there are piezoelectric sensors: Web a vibration sensor is a measuring device. Texas instrument’s sensortag is a great product that showcases ti’s bluetooth low energy system as well as 10 different sensors.

Web accelerometers are the most accurate way to detect vibration, and we’ll learn about them in another article. Vibration is not inherently bad — every rotating machine has a unique vibration signature. Web a vibration sensor is a measuring device.

The data gathered from the sensor is the vibration frequency, amplitude, phase angle and the form of the vibration. Now that we know what vibration is, let’s look at the different types of sensors to monitor vibration. It comes in at the incredibly low price of less than $30 (you wonder if ti loses money on these?!).

Therefore, This Paper Attempts To Use Vibration Sensors To Detect The Vibration Signals Emitted During The Welding Process, Together With The Current Signals And Molten Pool Images To Achieve The Identification Of Welding Defects.

These sensors are strategically attached to different machinery parts, and their readings are interpreted through vibration analyzers or. Web choosing the right vibration sensor is paramount to ensuring accurate data collection and effective maintenance strategies. Vibration sensors can be used to give maintenance teams insight into conditions within key assets that might lead to equipment failure, allowing them to predict the m. It measures the amplitude and frequency of vibration of the system under study.

Unique Vibrations Are Characterized By Frequency, Amplitude, Phase, And When Using Proximity Sensors, Position.

Ifm vibration monitoring systems help you avoid unplanned downtime in the middle of production by providing vibration data to assess and evaluate the condition of your machine in real time. Web second, while only one sensor is used in the dlv method to detect the damage location, the effect of sensor position on the performance of the dlv approach is not investigated yet. Web similar to how there are sensors that will detect light or emit light on the same principle, there are piezoelectric sensors: When a machine’s vibration measurements change, though, it can be an indication of.

Web Accelerometers Are The Most Accurate Way To Detect Vibration, And We’ll Learn About Them In Another Article.

Web types of vibration sensor. Shock sensors and knock sensors can be used to detect closing doors, excessive vibration in machinery, or collisions in remote controlled vehicles. In today's blog, we'll go over the basics of piezoelectric sensors and how they work! Having access to this data allows the user to predict an oncoming fail of such machinery and.

Web The Vibration Signals During The Process Can Be Used To Understand The Fusion Of The Weld And The Quality Of The Weld.

Serving around the globebased in houston, txaward winning technology But for some projects, you don’t need such high accuracy. Web a vibration sensor is a device that measures the amount and frequency of vibration in a given system, machine, or piece of equipment. Web a vibration sensor is a measuring device.