Tig Welding Weave Patterns

Tig Welding Weave Patterns - Mig welding involves feeding a continuous wire electrode through a welding gun and creating an arc between the wire and the workpiece. Smoothtool offers four main patterns to choose from: A new trending thing in the welding process is the “mig like tig” technique. If it’s a butt joint with a groove weld, it’s a 3g position. Each one of these dabs makes a circular shape as they are stacked on top of each other. We’ll hit on the latter in a bit, but right now let’s focus on the former.

Each one of these dabs makes a circular shape as they are stacked on top of each other. Today is a fun one! The other basic positions are flat, horizontal, and overhead. But it does not have to be slow. In this video of a welder laying down a cap weave on a 6 pipe joint, you might notice that he is running pretty hot and pretty fast.

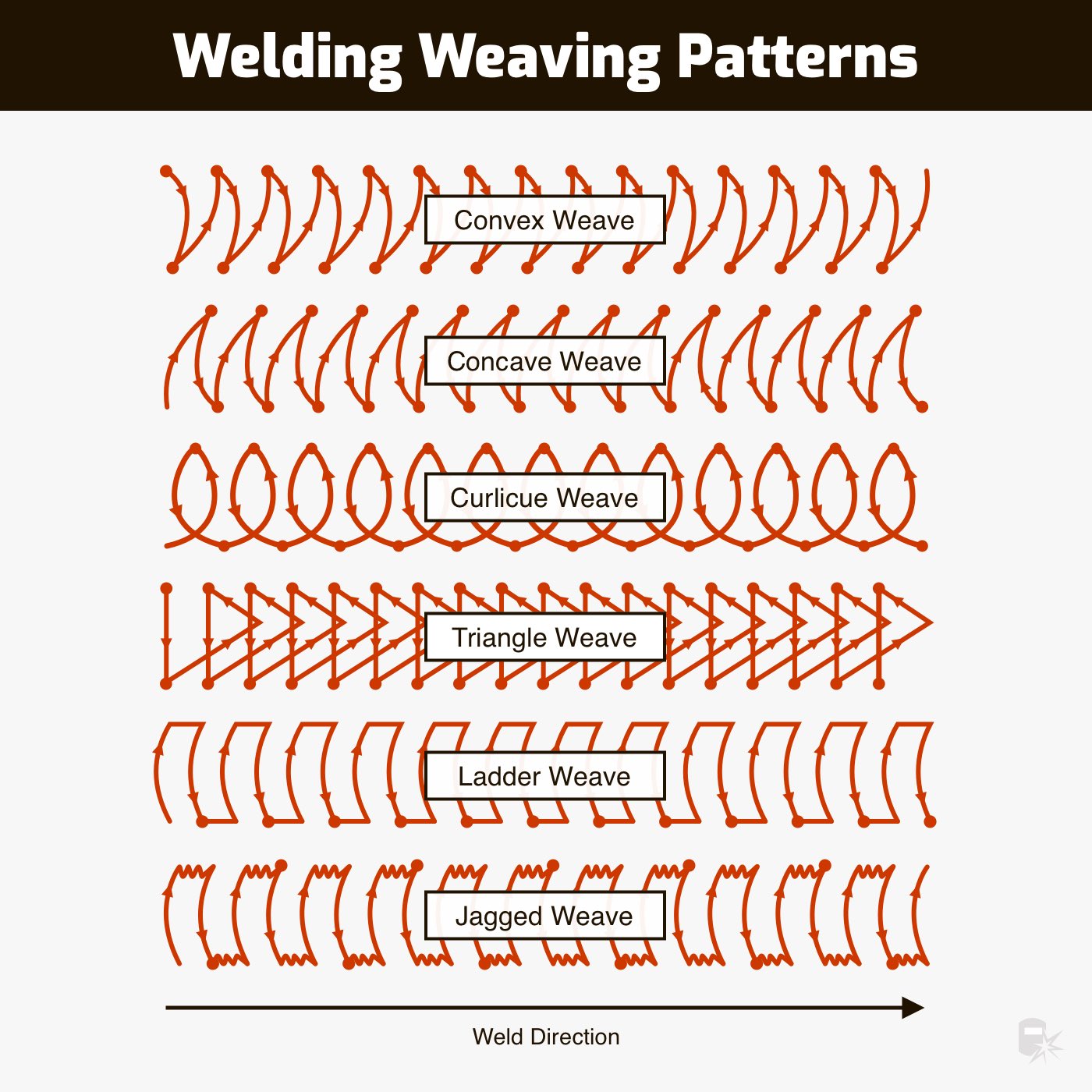

You will make a weaving pattern in order to cover a larger area. Web in this video we look at one way of how to do a freehand tig weave. Web tig welding a weave cover pass on pipe joint using a freehand tig welding technique. The most common sticking welding pattern is the weave. Web there are basically two ways to weave a tig weld:

Web generally speaking, there are two main welding bead techniques and patterns: Web users can access a variety of weaving patterns through the weld node’s parameters tab. The wider the gap between the pipes, the wider the grooves that. Web in order to test my new electric welding machine, i recorded the basic basics of electric welding in the video..

There is a perception that tig welding to be a really precise but very slow welding process. If you are a beginner, you probably have seen the pictures on instagram or facebook labeled #weldporn. Web improve your tig welding with tig tips and tricks and weld calculators, or learn to tig weld with training materials and mobile apps. Web generally.

There is a perception that tig welding to be a really precise but very slow welding process. Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°. Web although this can produce a sound weld, using a weave as a welding beads.

You will make a weaving pattern in order to cover a larger area. In this video of a welder laying down a cap weave on a 6 pipe joint, you might notice that he is running pretty hot and pretty fast. Today is a fun one! The other basic positions are flat, horizontal, and overhead. Web tig welding a weave.

But it does not have to be slow. Web to perform a weave bead in tig welding, the welder should: There is a perception that tig welding to be a really precise but very slow welding process. The other basic positions are flat, horizontal, and overhead. Mig welding involves feeding a continuous wire electrode through a welding gun and creating.

But it does not have to be slow. Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°. Web the two main types of welding bead patterns are stringers and weaves. This is because as the tig arc is traveling, the welder.

Web in this video we look at one way of how to do a freehand tig weave. Web tig welding weld [hagojibi] 393k subscribers subscribe 5.7k share 419k views 2 years ago #happy_new_year_2021 hello everyone. Use a moderate travel speed, not too fast or too slow keep the tig torch at a consistent angle and distance from the workpiece keep.

If you have a fillet weld in a tee or lap joint, it’s called a 3f position. Tig weaves are some of my favorite welding exercises because they offer some gret challenges when it comes to torch positioning and puddle control. This waveform offers high heat input, coupled with good puddle control and arc stability. Web vertical welding is one.

Web to perform a weave bead in tig welding, the welder should: Web tig welding weld [hagojibi] 393k subscribers subscribe 5.7k share 419k views 2 years ago #happy_new_year_2021 hello everyone. Use a moderate travel speed, not too fast or too slow keep the tig torch at a consistent angle and distance from the workpiece keep the tungsten electrode perpendicular to.

Web learn tig welding tips, best practices, and tricks of the trade for beginning and intermediate welders from metalworker ron covell. You use this motion to make cover welds over stringer beads (multipass welding). Web although this can produce a sound weld, using a weave as a welding beads pattern can benefit wider joints and straight welds. In this video.

Tig Welding Weave Patterns - Mig welding involves feeding a continuous wire electrode through a welding gun and creating an arc between the wire and the workpiece. This waveform offers high heat input, coupled with good puddle control and arc stability. Web improve your tig welding with tig tips and tricks and weld calculators, or learn to tig weld with training materials and mobile apps. Web in this video we look at one way of how to do a freehand tig weave. You use this motion to make cover welds over stringer beads (multipass welding). Use a moderate travel speed, not too fast or too slow keep the tig torch at a consistent angle and distance from the workpiece keep the tungsten electrode perpendicular to the workpiece vary the size of the weaving pattern to suit the thickness of the metal and the size of. Web the default waveform for the miller® diversion™ tig welding power source line is ‘soft squarewave’, which is a blend between a sine wave and square wave. Most people assume that all weaved tig welds are “walked.” it’s. This waveform is ideal for most welding jobs. Web learn tig welding tips, best practices, and tricks of the trade for beginning and intermediate welders from metalworker ron covell.

Weave bead welding is exactly as it sounds; Web the two main types of welding bead patterns are stringers and weaves. The other basic positions are flat, horizontal, and overhead. Web depending on the welding position, you might choose not to weave when welding because of the welder’s angle to the joint. In other words you use this when you are layering welds.

The other basic positions are flat, horizontal, and overhead. If you are a beginner, you probably have seen the pictures on instagram or facebook labeled #weldporn. But it does not have to be slow. In other words you use this when you are layering welds.

Certain positions lend themselves better to specific patterns, although you can choose the pattern based on your personal preferences in most cases. Web users can access a variety of weaving patterns through the weld node’s parameters tab. Walking the cup and freehand.

The most common sticking welding pattern is the weave. However, once you decide to create weld beads, there are different variations of the weave pattern which. Web the default waveform for the miller® diversion™ tig welding power source line is ‘soft squarewave’, which is a blend between a sine wave and square wave.

Most People Assume That All Weaved Tig Welds Are “Walked.” It’s.

Web users can access a variety of weaving patterns through the weld node’s parameters tab. Weave bead welding is exactly as it sounds; But it does not have to be slow. It's used when you make two or more welds on the same seam.

This Waveform Offers High Heat Input, Coupled With Good Puddle Control And Arc Stability.

Web tig welding beads. Today is a fun one! The most common sticking welding pattern is the weave. Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°.

This Is Because As The Tig Arc Is Traveling, The Welder Is Adding Evenly Spaced “Dabs” Of Filler Metal With Their Other Hand.

You will make a weaving pattern in order to cover a larger area. The wider the gap between the pipes, the wider the grooves that. In other words you use this when you are layering welds. Web weave bead welding involves making a weaving pattern in order to cover a larger surface area.

Smoothtool Offers Four Main Patterns To Choose From:

Use a moderate travel speed, not too fast or too slow keep the tig torch at a consistent angle and distance from the workpiece keep the tungsten electrode perpendicular to the workpiece vary the size of the weaving pattern to suit the thickness of the metal and the size of. We’ll hit on the latter in a bit, but right now let’s focus on the former. Learn to weave with tig. Web generally speaking, there are two main welding bead techniques and patterns: